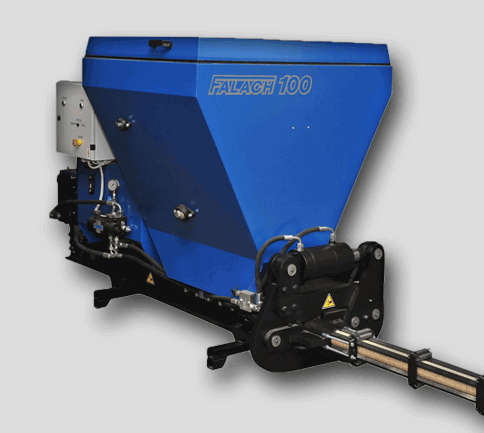

Description

In the table below, we provide you with important technical parameters of the Falach Cube 20 SP (single-phase) briquetting press for your information.

| Dimensions–length-width–height | 130-74-112 cm |

| Briquette diameter | 30 x 30 mm |

| Press capacity | 10-25 kg/hour |

| Briquette length approx. | 6-50 mm |

| Weight of press | 233 kg |

| Hopper volume | 0,28 m3 |

| Pump motor input | 3 kW |

| Power consumption | 1,5 kW/hour |

| Required input voltage and current | 1x230V, 32A |

| Oil cooler | no |

| Operation | continuous |

| Automatic switching-out | no |

| Maximum percentage of moisture | 15 % |

| Specific weight of briquettes | 900-1100 kg/m3 |

| Maximum noise level | 62 dB |

The equivalent sound pressure level at the briquetting press operator’s station does not exceed 70.0 dB (68 dB).

Warranty and after-warranty service of Falach Cube 20 SP briquetting presses

Falach provides a 12-month warranty on all types of Falach briquetting presses and further undertakes to maintain after-warranty service for 10 years after the warranty period has expired.

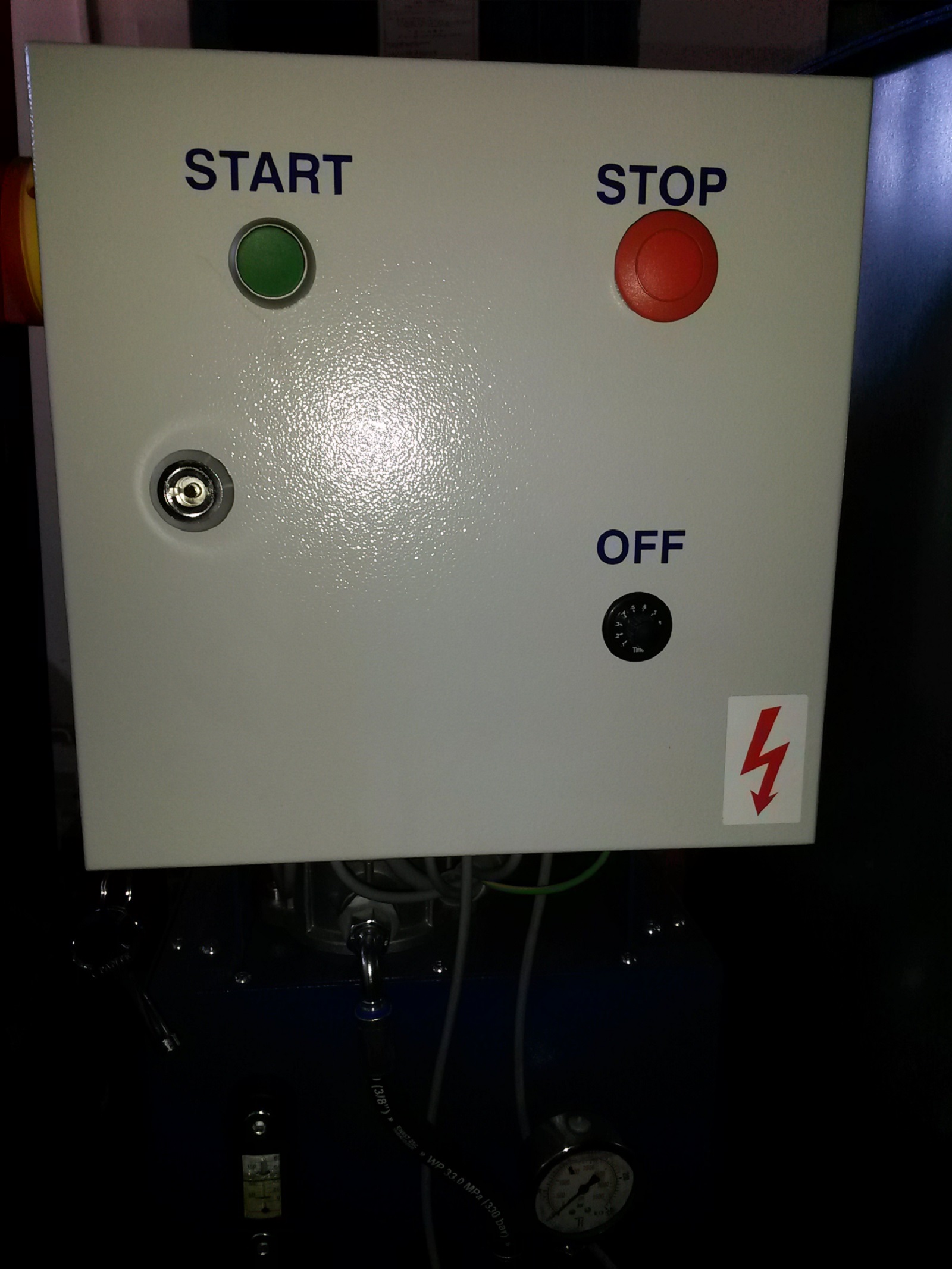

Important information when operating the briquetting machine

It is prohibited to connect the device to a distribution system that does not comply with applicable regulations (the permissible fluctuation of the nominal value of the supply voltage is 10%).

Do not exceed the maximum pressure setting of 10 MPa.

All repairs, adjustments, maintenance and cleaning of the machine should only be carried out when the machine is switched off and disconnected from the power source.

Do not expose the briquetting press to an excessively humid environment and it must be protected from weather conditions.

While the machine is running, avoid direct contact with moving parts of the press (especially the front clamp and pressing die, feed wheel inside the hopper).

It is forbidden to extinguish the press under electrical voltage with a water or foam extinguisher, as there is a risk of electric shock (recommended powder, snow or halon extinguisher)

We confirm that the Falach Cube 20 SP briquetting press complies with the conditions of the regulations and standards listed below

ČSN EN ISO 12100-1, ČSN EN ISO 12100-2, ČSN EN 60204-1, ČSN EN 61000-6-4, ČSN EN 55011, ČSN EN 982, ČSN EN 954-1, ČSN EN ISO 14121-1.

The post-cooling path is especially for MDF materials (but also for others). It serves to reduce the temperature of the finished briquettes.

Falach briquetting presses

The design of Falach presses is designed to guarantee high durability and low failure rate. The structural elements of Falach briquetting presses are commonly available in the Czech Republic.